Your Solution Set to Medical Device Product Design

Solutions

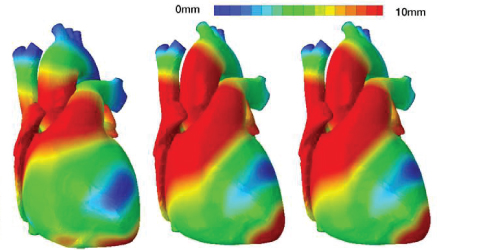

SOLIDWORKS Simulation

There are multiple benefits of 3D simulation-driven design. This type of testing is a much more affordable option than physical testing and prioritizes patient safety. Utilizing simulations makes it easier to see what components on the device are functioning properly and what could use additional work before moving to final production. This level of analysis on the front end can also help determine how to improve a device's performance, streamlining production and creating a device that provides more value and safety for patients.

Solutions

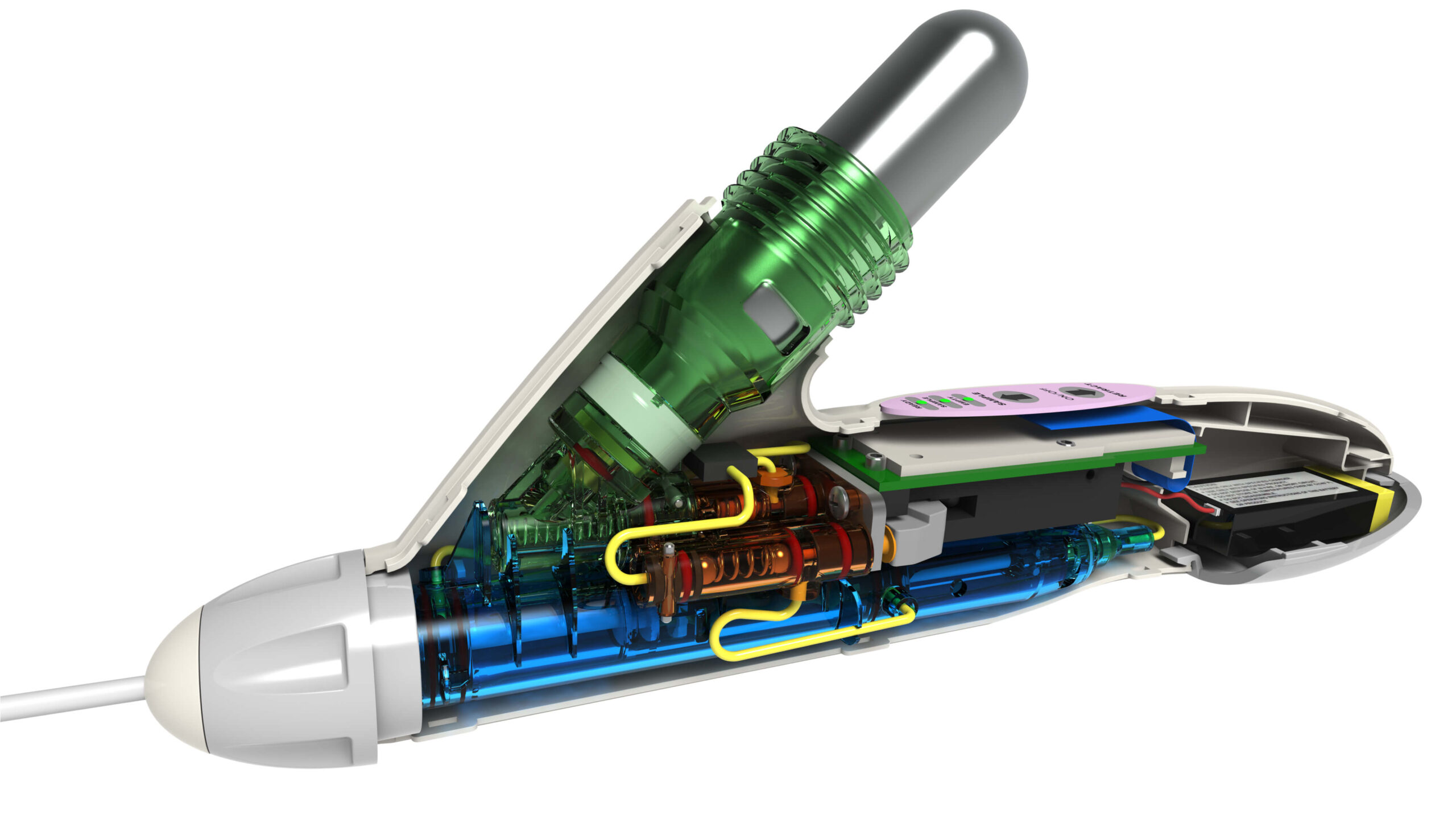

SOLIDWORKS Plastics

Most small medical devices are manufactured with plastics. SOLIDWORKS Plastics simplifies injection molding simulation for small medical device designers. It predicts manufacturing defects, improves part quality, and speeds up time to market by simulating plastic flow during injection molding, helping to avoid costly mold rework.

Solutions

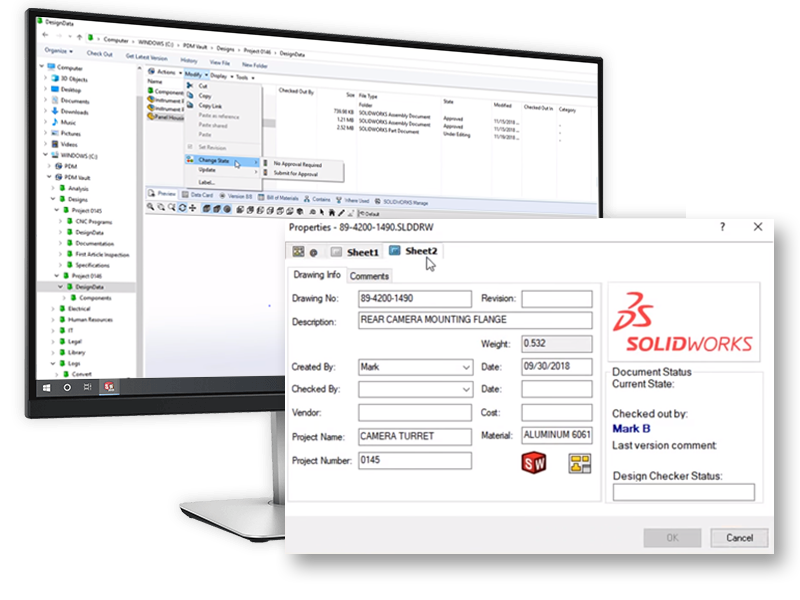

SOLIDWORKS PDM

SOLIDWORKS PDM system helps manage documents like engineering change orders and instructional materials internally. It allows users to check in and out documents, track revisions, and maintain records with features like history recognition and revision numbering. This system ensures all documentation is monitored and changes are tracked, which is essential in the medical industry for FDA compliance.

Solutions

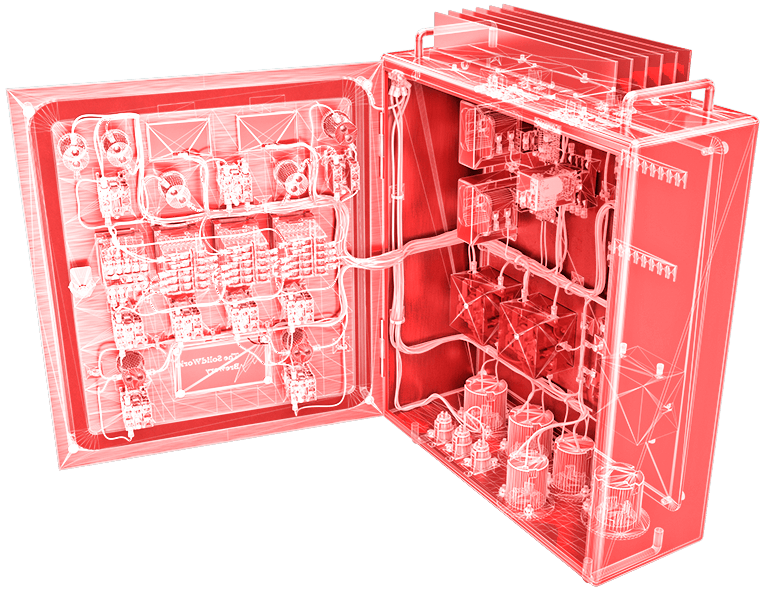

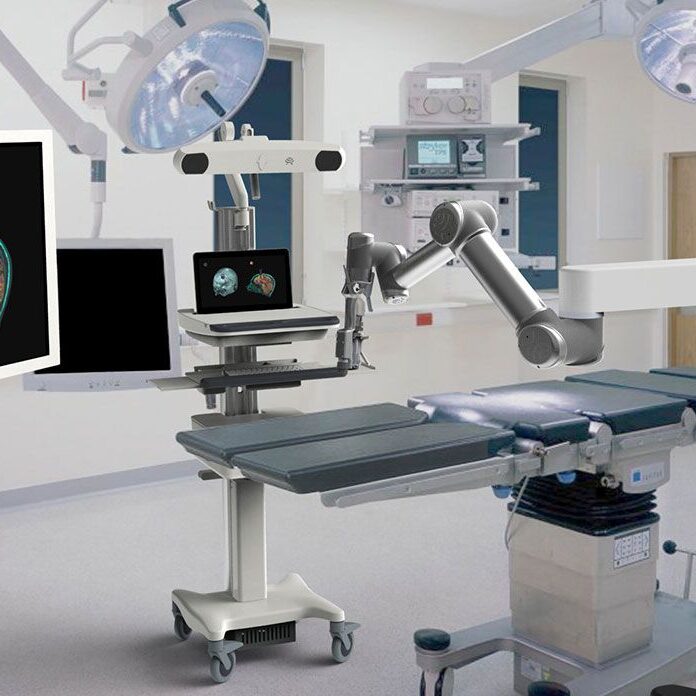

SOLIDWORKS Electrical

SOLIDWORKS Electrical allows medical equipment makers to include mechanical and electrical components into their product designs. With the use of a shared data model, integrating different electrical systems such as wiring, logic controllers, power systems, and visual interfaces is made easier and may be completed in tandem with the industrial and mechanical design teams.

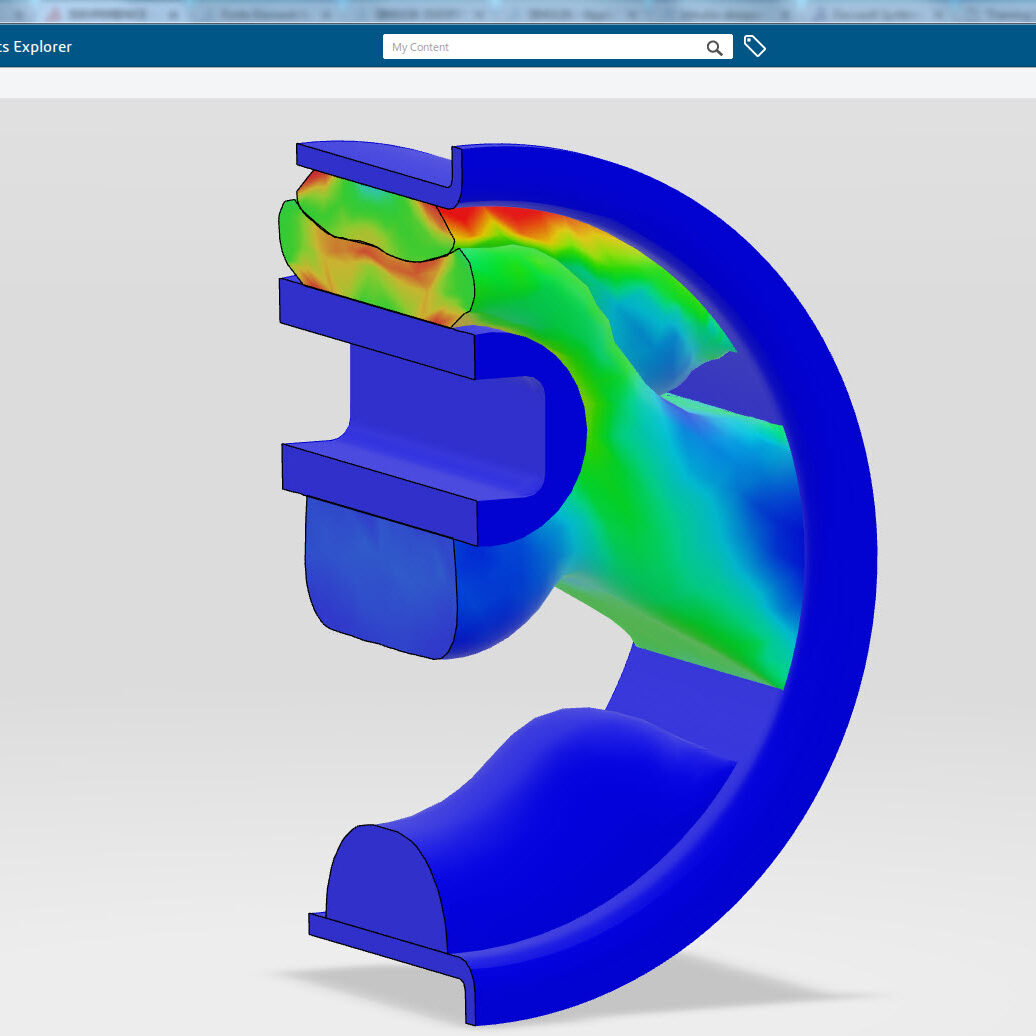

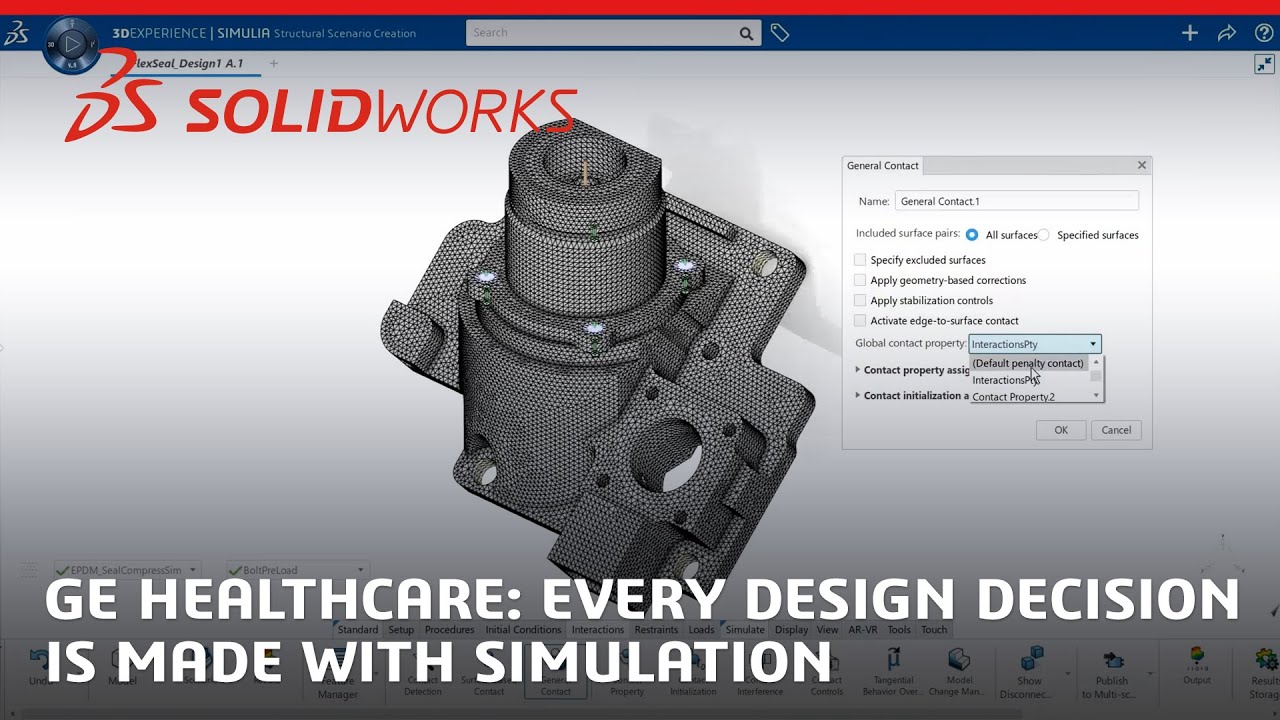

Simulation Drives Every Design Decision at GE Healthcare

Discover how GE Healthcare engineers utilize SOLIDWORKS and 3DEXPERIENCE Works Simulation to accelerate product development and innovation of anesthesia delivery products. The engineers rapidly compared and validated the best design alternatives with accurate simulations of complex non-linear structural of elastomer material with complex contact and fluids problems.

Markforged

Additive Manufacturing

Streamline Medical Device Engineering with Virtual Prototyping and Testing

Markforged offers a variety of desktop, industrial, and metal 3D printers, allowing you to prototype and manufacture fixtures, work holding, and aids for the medical device manufacturing process. This accelerates time-to-market and reduces costs by bypassing traditional manufacturing methods.

Applications: Ergonomic tools, assembly trays, cosmetic parts, end-of-arm tools, lightweight brackets, general high-wear tooling, functional prototypes, custom wrenches & sockets.

Accelerate Innovation with 3D Printing for the Medical Device Industry

Quickly manufacture functional parts with minimal overhead, providing medical professionals with products faster than ever before.