We’ve been hosting educational events on our 3D printing partnerships and diving into printer lines, materials, and the wide range of possible applications you can implement, that often go beyond prototyping.

Yesterday, we hosted our latest mini series inspired by Engineer 3D!, our biennial conference on every and any 3D solution you can imagine within both the SOLIDWORKS platform and Markforged / HP 3D printers.

As we grow our exciting partnerships with both Markforged and HP 3D Printing, we are continuing to invest in valuable experiences (and as much as possible, user group inspired experiences) to broaden the types of applications Midwest manufacturers in our industry are using, and to educate on the advantages of different materials.

Yesterday’s series, in particular, was on Markforged technology.

We dived into Markforged’s composites (used in Industrial and Desktop series printers) that have incredible material strength often not fully understood or known about in the industry.

Composite materials, and the ability to reinforce them with strands of carbon fiber and the like, can be as strong as, or stronger than metal. Markforged composites and reinforcement technology are unique in this way.

More importantly, we work every day with companies to identify the right material fit for them.

What’s most exciting for us is hearing how our customers are using their Markforged printers for applications around welding, fixturing, assembling, packaging, and more. Johnson Level is one such company.

While this event covered solely Markforged, we are hosting an April 2nd event on HP 3D Printing technology, which specializes in production-grade plastics at high volumes. We’ll cover how this multijet fusion technology works, the available printers, and which offer full color parts excellent for prototyping.

Many of our customers are using the HP full color printing to bring products to bid and win new projects before their competitors.

Please contact us if you would like to be put on the waitlist for that April HP event.

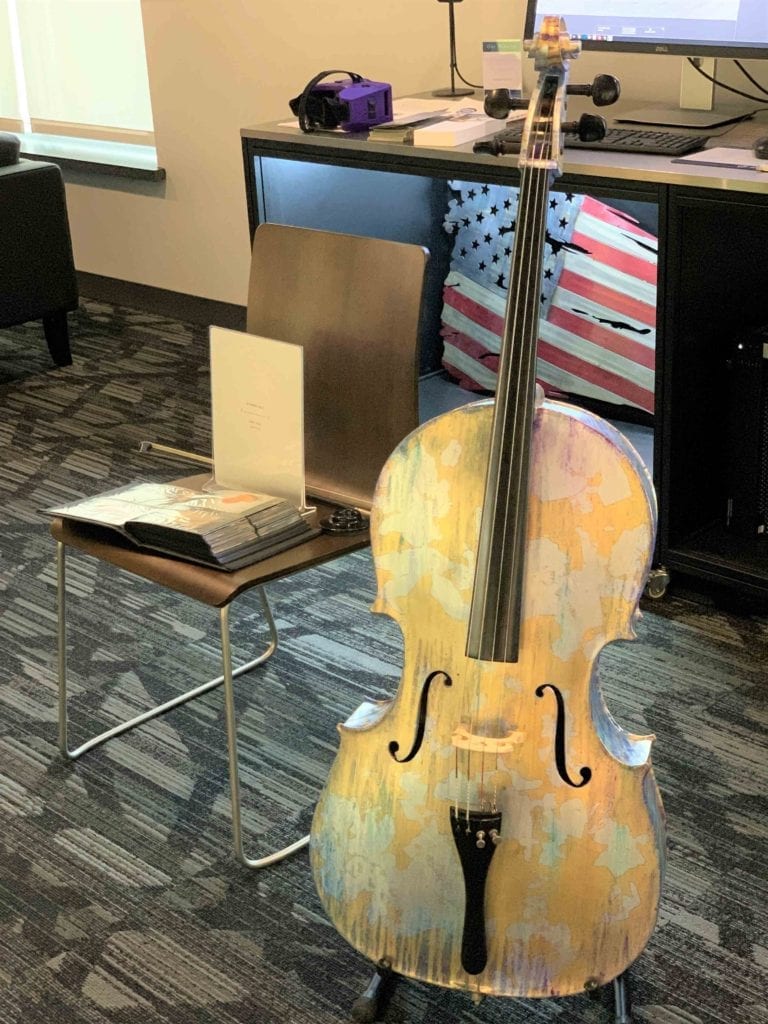

Last but not least, we also had the opportunity to feature another partnership. Maddie Frank of UW-Milwaukee brought by her 3D printed playable cello. Read more about Maddie and her award-winning cello in our additive blog article.

Learn More

We hope you’ve enjoyed this blog! If you have any questions on 3D printing and additive manufacturing, please contact us! If you’re interested in SOLIDWORKS, we’d also be happy to talk with you.

Share

Meet the Author