Fluid Dynamics During Intubation – Developing an Intubation Chamber for Medical Personnel

Learn how SOLIDWORKS Flow Simulation helped evaluate several design iterations of an Intubation Chamber and progressed its development for medical personnel.

Quickness & Rapid Response Using Simulation

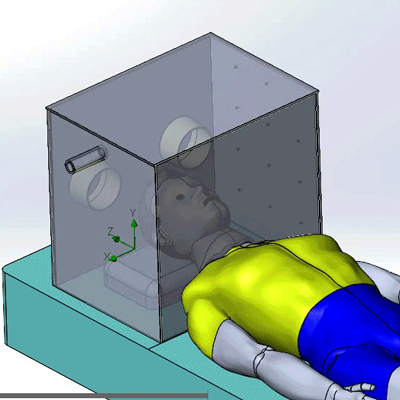

GSC was asked by Jeff Wong of Paradigm Design Inc., to help with the simulation and development of an Intubation Chamber for medical personnel. This device allows medical personnel to have another layer of protection in the fight against COVID19 during the intubation procedure.

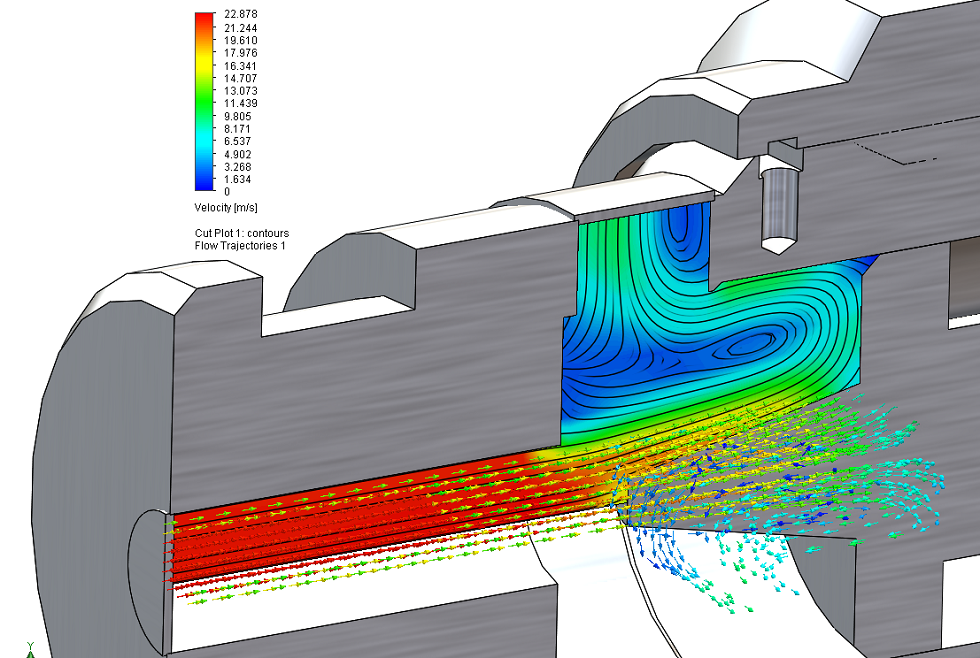

We used SOLIDWORKS Flow Simulation to accurately model a patient coughing in order to evaluate and validate the Intubation Chamber design. When modeling, we mimicked the coughing of aerosolized particulates during the insertion of endotracheal tube, before the patient gets connected to a ventilator.

The design is a clear, plexiglass, negative air pressure chamber, that is placed over the head of the patient. Air is evacuated from the chamber at one liter per second. Design iterations involving location, number and size of the air inlets and the air outlets / evacuation orifices were performed so that the aerosolized virus particulate is completely evacuated from the Intubation Chamber quickly and safely.

The ease and power of SOLIDWORKS Flow Simulation software enabled us to evaluate the design and perform several design iterations in days with confidence and efficiency. We successfully decreased the evacuation time from several minutes, to seconds.

Background on Medical Device Manufacturing & Environments

Rooms with COVID patients need to ideally be negative pressure rooms, to protect everyone. Air flows through filters and gets sucked out. We have to make sure that a variety of rooms at hospitals and clinics are negative pressure rooms such as waiting rooms, janitor’s closets, ICU units, and infectious disease rooms.

Operating rooms, for example, are positive pressure. There are neutral or no-pressure rooms, such as recovery rooms. Hospitals can switch their ventilation systems, but this takes many hours and a lot of money to convert rooms to be this way. This involves putting HVAC and doors in different spots.

To first start this process, you have to model the intubation chamber in SOLIDWORKS CAD, with parameters and constraints. You think about the openings, vacuum tubes, and suction levels, and how to cover up any unnecessary openings. This was a first iteration attempt at modeling and altering the design, considering what data we had, the cost, and the air, aerosol, and fluid forces involved.

Flow Simulation is good for what it can do as a software. You have to consider particle size, and have that medical expertise known. Medical device projects such as these are good for academia for experimentation.

About Paradigm Design

Jeff Wong is a consultant at Paradigm Design, which specializes in medical and scientific instruments. He was asked to evaluate an intubation box in March of 2020. In the early days of the pandemic, the device was used during intubation, where a flexible tube is placed down the mouth. The patient is connected to a ventilator to pump air into the lungs, to assist with breathing.

The doctor tilts the head back to open the airway, but there’s a curvature to consider. The intubation box was designed to protect the doctor and an assistant from getting a direct hit of fluid during a cough. After passing his work onto biomedical engineering staff and students, Jeff’s hope was for them to adopt a design to their location, their specifics, and their staff. The hope is also that they optimized a completely new intubation box design considering shape, parts, storage, cleaning costs, etc.

Interested in Learning More?

Fill out the form below to watch our On-Demand Webinar

More on SOLIDWORKS Flow Simulation

Easily simulate fluid flow, heat transfer, and fluid forces. Run “what if” scenarios, and efficiently analyze the effects on immersed or surrounding components. Intuitive tools like CFD (computational fluid dynamics) enable you to simulate realistic liquid and gas flow with real-world conditions.

Share

Meet the Author