SOLIDWORKS Electrical is a powerful tool that allows your electrical and mechanical design teams to collaborate effortlessly without worrying about data loss or transfer. With engineer-specific tools and clear interfaces, electrical product design is simplified, allowing your team to spend less time on admin tasks and more on engineering.

Understanding the key benefits to help solve key critical business issues while integrating mechanical and electrical engineering makes life easier for your engineering designers. With GSC’s implementation services, we can accelerate your team’s adoption and upskill in a short time frame.

Why Implement with GSC For SOLIDWORKS Electrical

Key Benefits of SOLIDWORKS Electrical:

1. Quickly Generate Designs

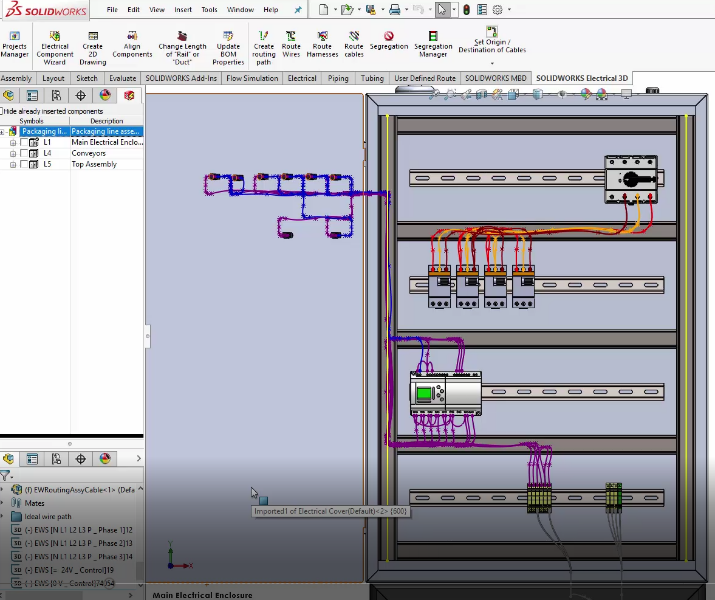

Are you regularly forced to produce complex methods to create innovative designs or modify existing versions? Do you have poor support for collaboration or inefficient tools to develop complex schematics and reports? Real-time, multiuser design tools in SOLIDWORKS Electrical allow you to reuse existing designs or develop complicated schematic designs with more simplicity. Not only that, but you can also leverage single line schematics into detailed multi-line power and control, PLC schematics, and terminal strip management tools.

2. Avoid or Reduce Hidden Costs

Oftentimes, design changes are not synced between MCAD and ECAD, there may be multiple bills of materials (one for electrical; one for mechanical) and incomplete specification of electrical details. SOLIDWORKS Electrical makes communication between departments seamless, reduces costs, and eliminates disjointed bills of materials. It also ensures:

- Schematics are bi-directionally linked and allow multi-user interaction in real-time

- ECAD and MCAD share a common database, ensuring consistency and facilitating the creation of a single, unified bill of materials

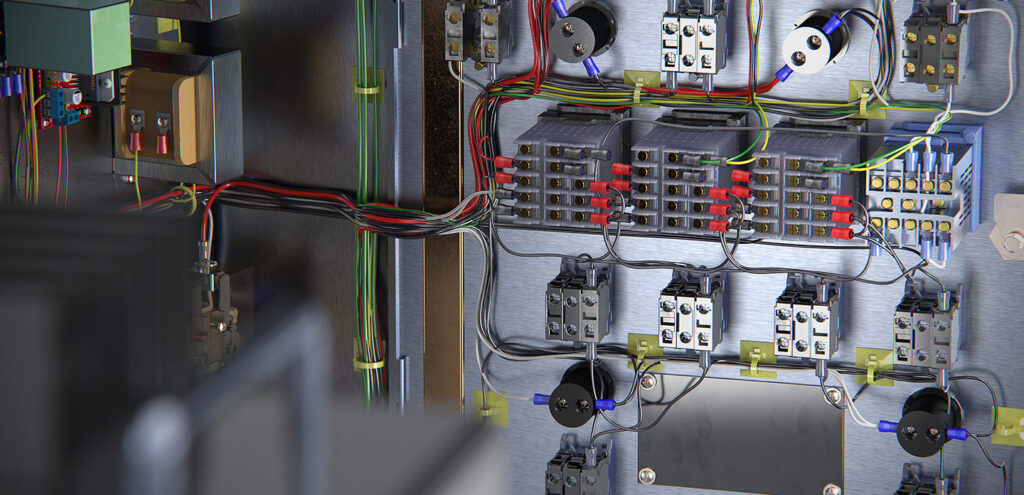

3. Reduce Manufacturing Defects and Scrap

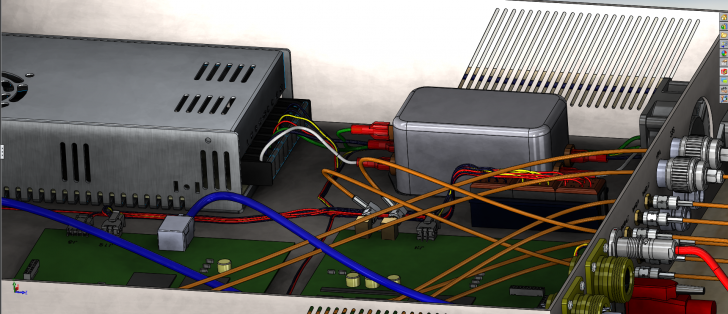

Reducing manufacturing defects and material scrap can help your company minimize wasted materials and expenses. Inexact planning of cable/wire lengths, incomplete design, and items’ planning can add to significant costs. With 2D Schematics linked to 3D SOLIDWORKS assembly, you can facilitate verification of proper fit, planning of all wire, cable, harness routes, and calculation of all wire lengths prior to any assembly.

4. Avoid or Reduce Time-to-Market Delays

When electrical and mechanical processes are coordinated, teams can operate in parallel to save time. SOLIDWORKS Electrical helps facilitate the combination of mechanical and electrical aspects into a single bill of materials. It also easily links the component database to MRP/ERP to ensure proper part numbers, pricing, supplier, lead time, and other relevant data are captured at the time of design for accurate planning.

As with most new applications, users must modify workflows, develop new skills, and become acquainted with the interface while meeting deadlines. With our help, you can take advantage of these benefits and focus more on designing and quickly transforming new ideas into innovative products.

Ready to Start Implementing?

At GSC, we consider implementation an essential part of the process. With nearly limitless capabilities to meet your demands, it can be difficult to know which path is right for your company. In fact, out of the hundreds of companies we have worked with, no two SOLIDWORKS Electrical implementations have been the same.

With decades of real-world electrical design experience, our engineers can help you set up your project environment, project structure, and symbols for immediate success. We optimize configurations to automate your processes and finish with customized training to empower your team with the tools and best practices they need to be successful. With expert training and assistance tailored to your needs, we are here to guide you through your electrical startup process.

What’s all involved in a SOLIDWORKS Electrical implementation? Download our whitepaper to learn more:

Share

Meet the Author