Metal X Series

Complete 3D Metal Printing Solution

World’s first Atomic Diffusion Additive Manufacturing (ADAM) Machine

Based on Markforged 4th generation composite 3D printing technology, the Metal X is a brand new kind of 3D printer. By printing metal powder bound in a plastic matrix, we've eliminated the safety risks associated with traditional metal 3D printing while enabling new features like closed-cell infill for reduced part weight and cost.

Design

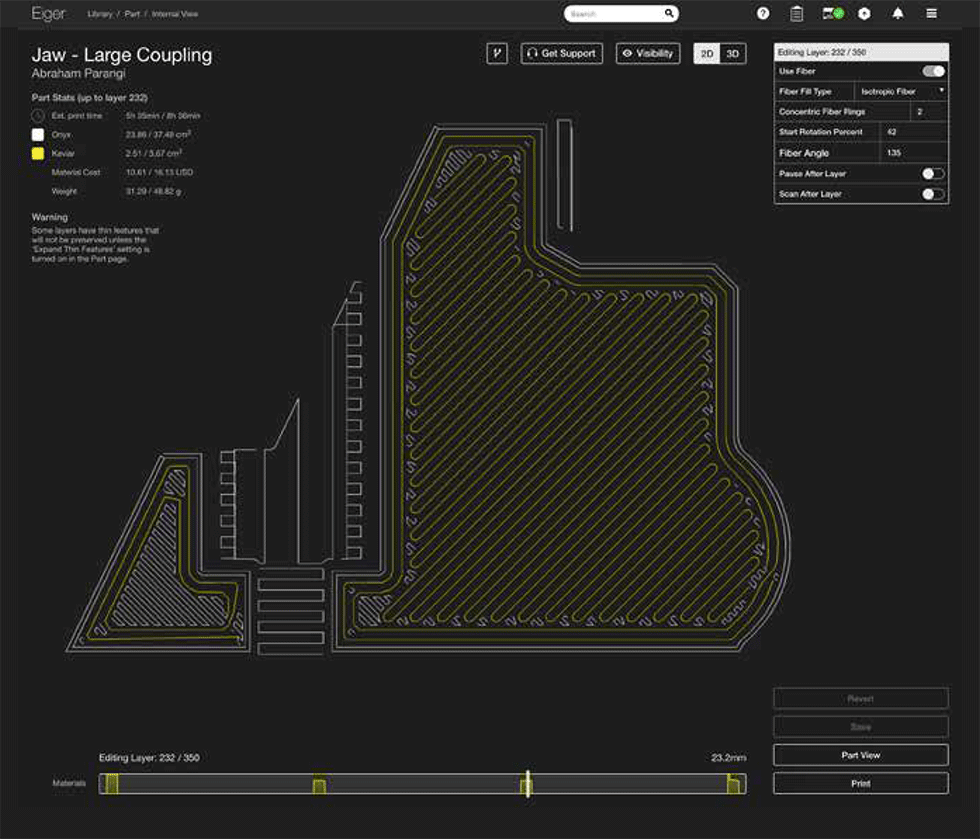

Upload the STL and select from a wide range of metals. The Eiger software does the rest making printing the right part easy.

Metal powder bound in plastic is printed a layer at a time into the shape of your part. Parts are scaled up to compensate for shrinkage during the sintering process.

Sinter

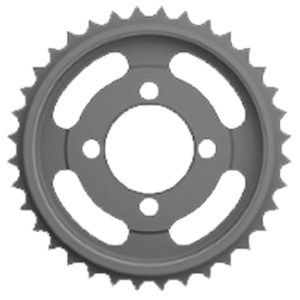

Printed parts go through a washing stage to remove some of the binder. They are then sintered in a furnace and the metal powder fuses into solid metal.

Part

Now comprised only of pure metal, the final parts are ready for use. They can be processed and treated just like any other metal parts.

Sinter-2

With a huge active hot-zone (19,644 cubic cm, 1,199 cubic in), the Sinter-2 is the perfect solution for large parts or batch production. This workhorse furnace sinters the full range of commercial-grade metals from their washed state into dense metal parts.

Wash-1

The Wash-1 immerses the green part in a specialized fluid which removes the primary binding material, leaving the part semi-porous so the remaining binder can easily burn off during sintering. This debinding step purifies the final metal part and helps keep your sintering furnace clean.

With a fully enclosed build chamber, ultra-quiet motion system and environmentally controlled material storage, our 3D printers are equally at home whether in the office or on the factory floor.

Industrial Series

Composite 3D printing provides the strength you need for tooling and functional parts. The Industrial grade, large-format printers deliver exceptional accuracy, reliability and repeatability.

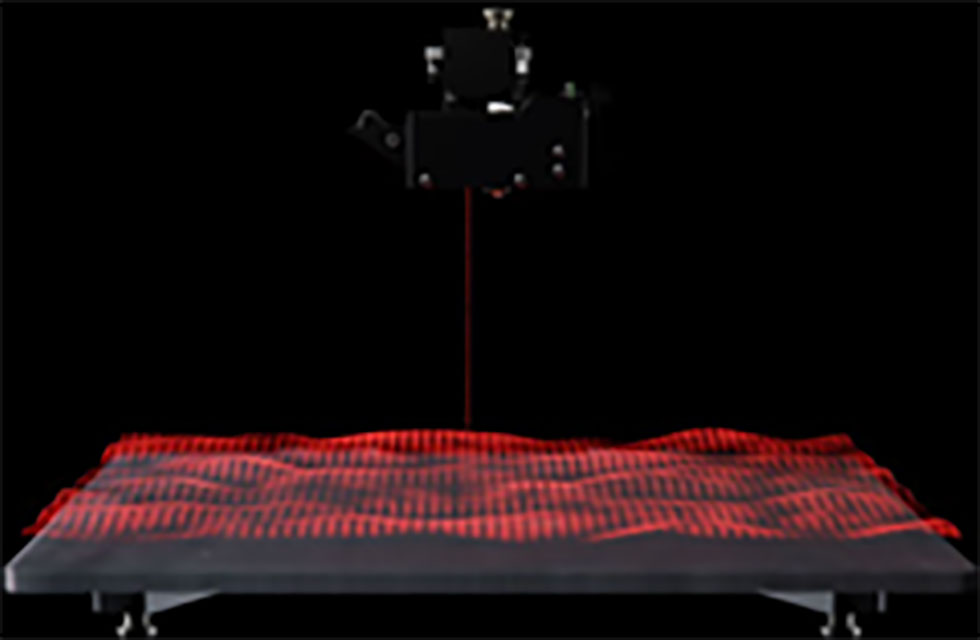

Laser Precision

With a built-in laser micrometer, the print bed is automatically scanned with 1µm accuracy to generate a contour map of its surface. By calibrating its measurements with extrusion readings to perfectly set nozzle height and active topography adjustment, your prints will come out exactly how you want them.

X7

Unparalleled performance without compromise —

The X7 delivers all the continuous fibers available without compromise.

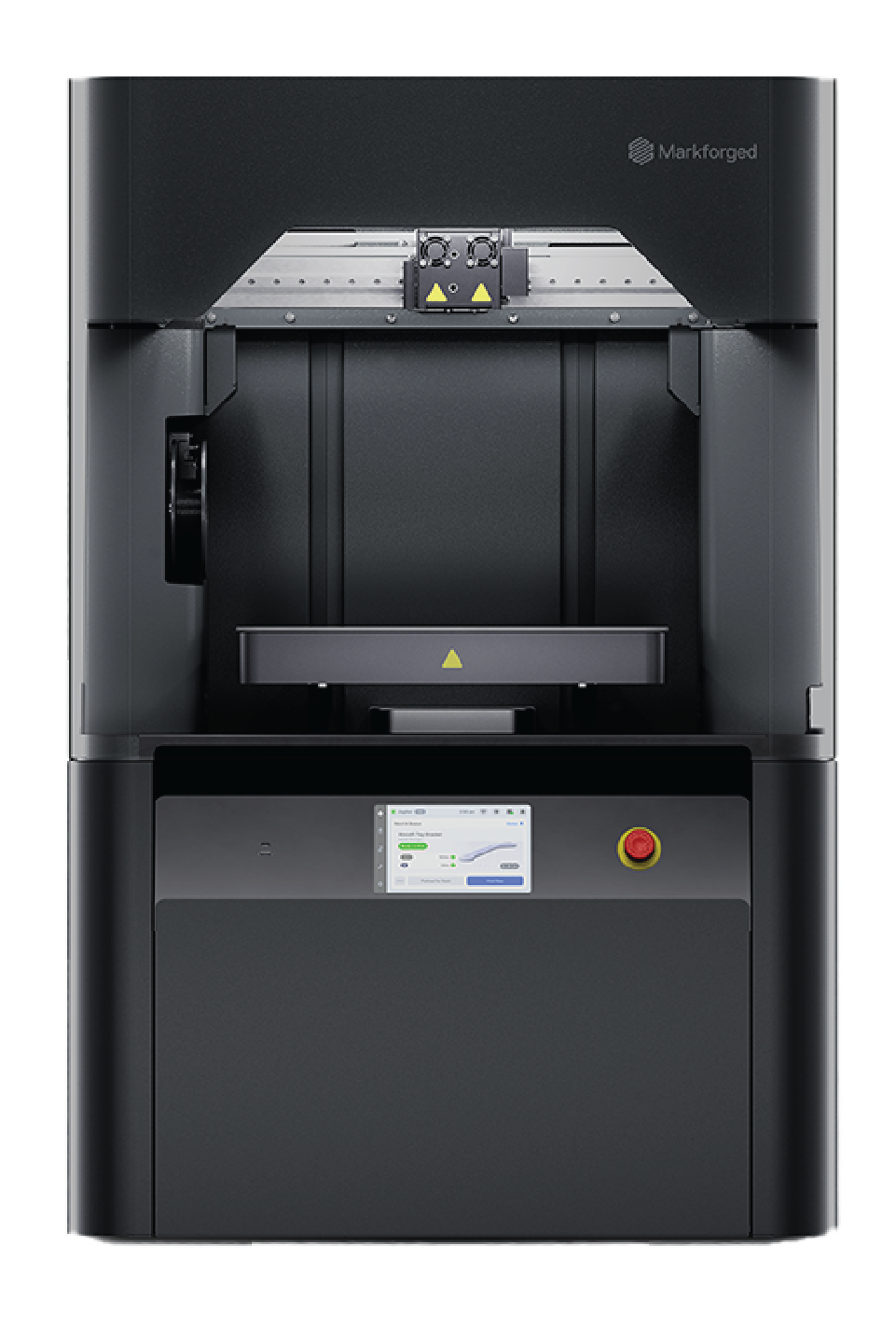

FX10

FX10 prints continuous carbon fiber reinforced parts for a wide range of factory floor applications — helping manufacturers increase speed to market, slash fabrication and inventory costs, and de-risk line down events.

FX20

The FX20 is capable of printing larger and more sophisticated parts faster than any other Markforged 3D printer. This next-generation additive manufacturing platform prints high-temperature thermoplastics reinforced with continuous fiber. These composite parts can withstand some of the world’s most demanding applications, including aerospace, defense, automotive, and oil and gas.

Working With Industrial 3D Printers

Learn how to gain manufacturing independence for applications throughout your line.

3D Printing Buyer's Guide

Get the specifications to help you choose the best 3D printer for your needs.

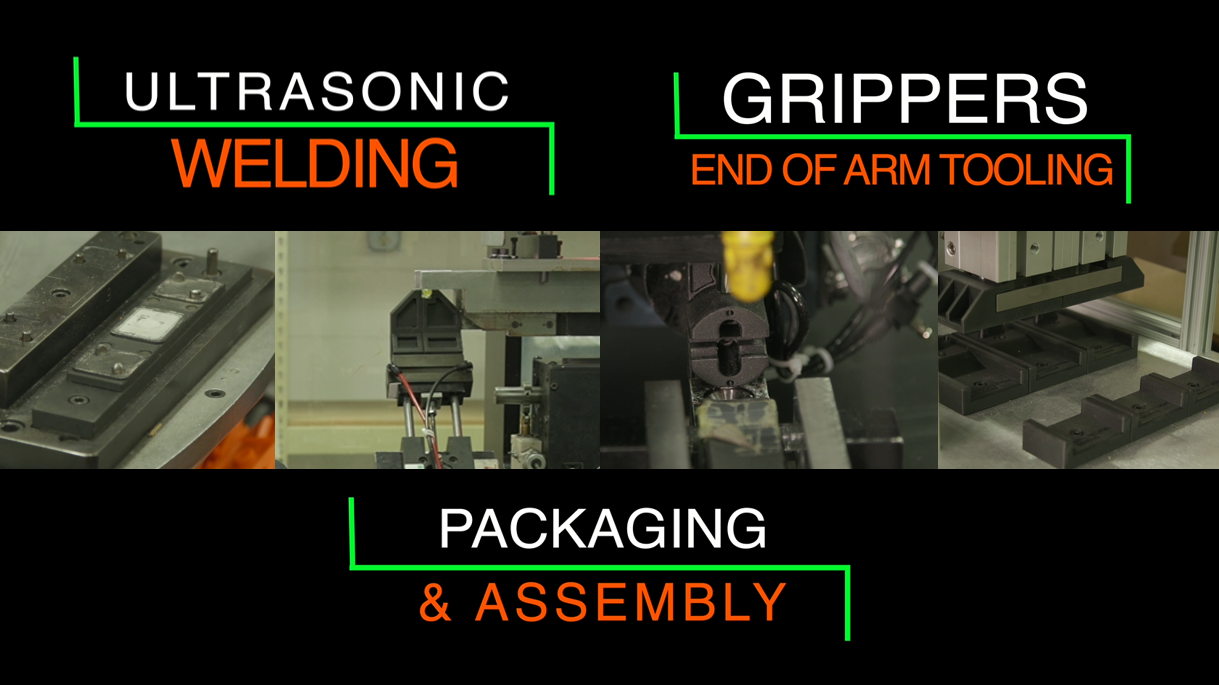

GSC Customer Success Story

Johnson Level purchased the Mark Two industrial grade printer and saw ROI within 9 months. New 3D parts make up their production line including an ultrasonic welding fixture, multiple grippers, packaging prototypes and a new assembly machine.

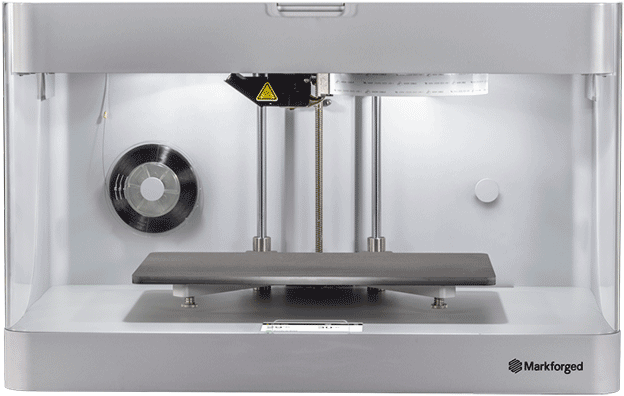

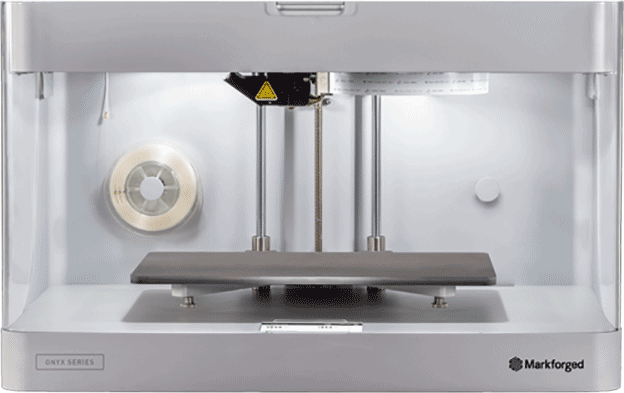

Desktop Series

Built on the same platform as the Industrial Series, these machines pack quality and reliability in a form factor that fits on your desktop.

Industrial-Grade Hardware

Every Markforged desktop 3D printer is built with designers and engineers in mind. Markforged 3D printers deliver the highest quality of parts—precise, repeatable, and strong.

Mark Two

High-strength printing in a wide range of materials —

The Mark Two unlocks all continuous fibers available without compromise.

Onyx Pro

Fast, affordable, impressive strength — The Onyx Pro introduces continuous strands of fiberglass to create stronger parts.

Cloud-connected software and a 4.3” touchscreen comes standard with every printer. Regular over-the-air updates mean that your Markforged products will stay up-to-date. Material usage tracking and out-of-material detection help monitor your printers and reduce waste.

With automatic version control, real-time fleet management, and cloud-based collaboration, Eiger is the world’s most advanced 3D printing software. Designed from the ground up to make manufacturing simpler, Eiger enables you to print plastic, metal, and composite parts straight from your browser right to your 3D printer.