Challenge

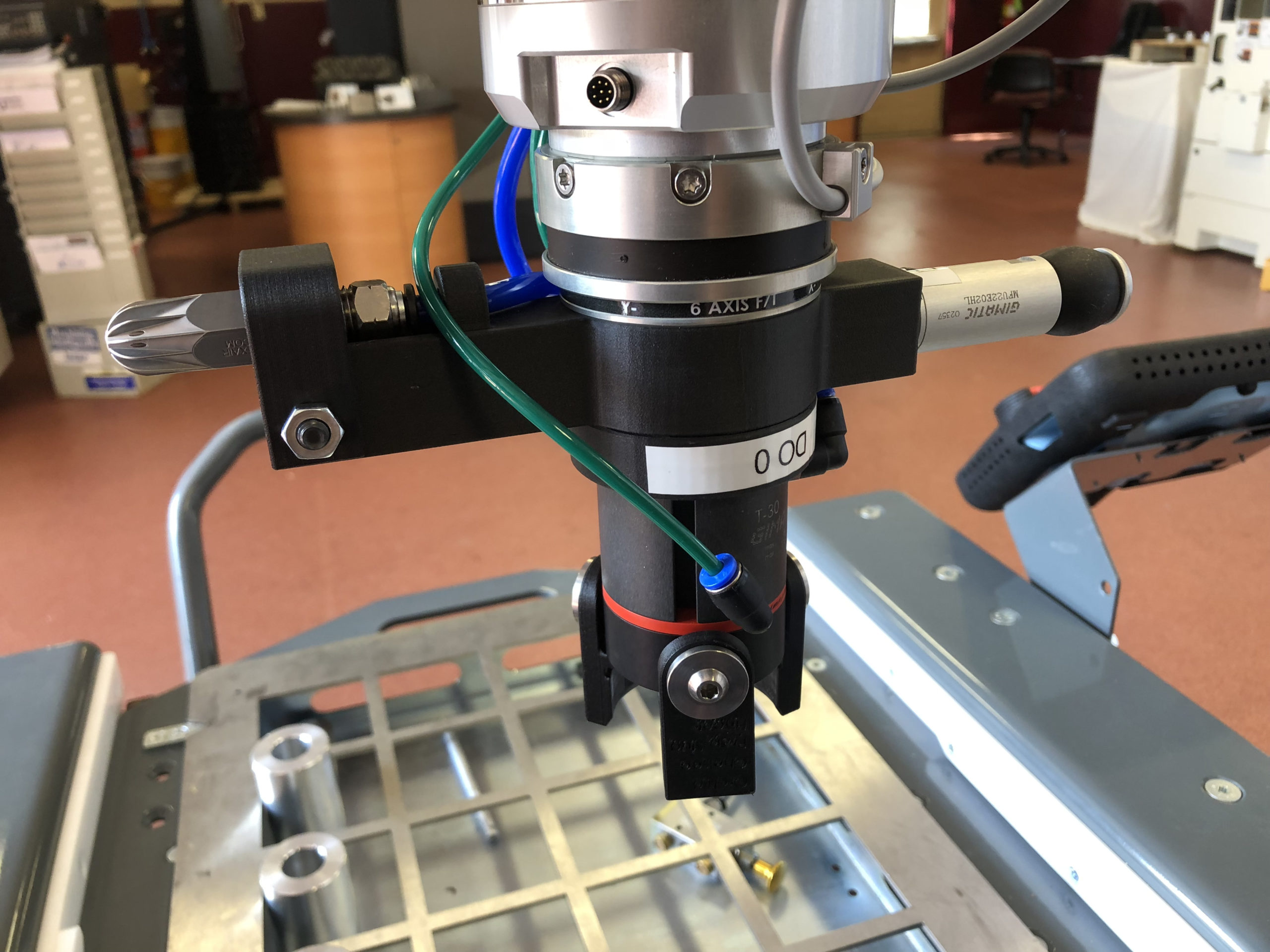

Industrial robots require specialized end effectors for various tasks. These end effectors need to be customized to the specific application, offer high precision, durability, and reliability. Traditional manufacturing methods for end effectors, such as machining or injection molding, can be time-consuming, expensive, and may not provide the desired level of complexity or customization.

Solution

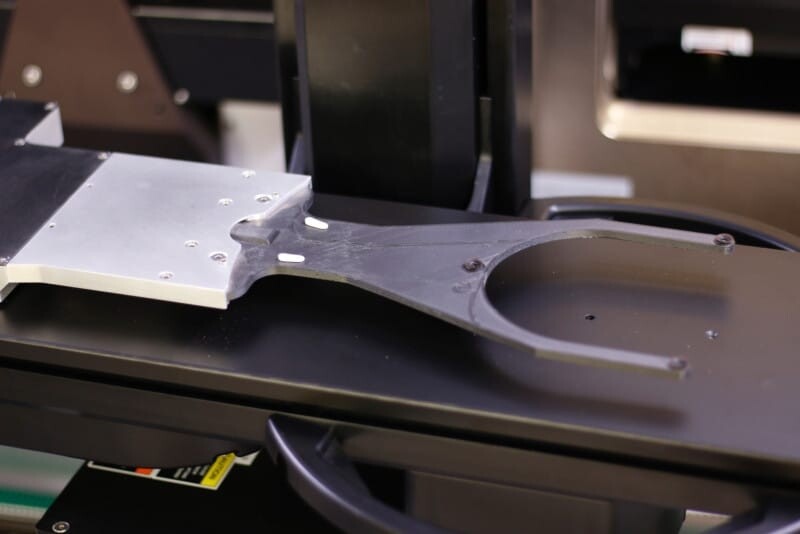

Markforged printers utilize continuous fiber materials such as carbon fiber and kevlar enabling you to produce end effectors that exhibit exceptional durability and resistance to wear. These materials provide the strength-to-weight ratio necessary for robust yet agile end effectors, enhancing the performance of your robotic systems. Additionally, Markforged's technology allows for intricate geometries previously impossible to achieve with traditional manufacturing methods.

Impact

Enhanced Efficiency: Customized end effectors optimized for specific tasks improve the overall efficiency of robotic operations, reducing cycle times and improving productivity.

Innovation: The ability to rapidly prototype and iterate designs encourages innovation in end effector development. This can lead to the discovery of novel solutions to complex automation challenges.

Reduced Costs: 3D printing eliminates the need for extensive tooling, reducing upfront costs and minimizing material waste, which is especially beneficial for low-volume or specialized applications.

Lightweight and Strong Parts: The use of composite materials results in lightweight yet robust end effectors. This can improve robot performance, reduce wear and tear, and increase the lifespan of both the end effector and the robot arm.

Adaptability: The quick and cost-effective production of end effectors enables companies to adapt to changing manufacturing needs and easily replace or modify end effectors as tasks evolve.

Competitive Edge: The ability to rapidly develop and deploy customized end effectors can provide companies with a competitive advantage in the automation and robotics industry.

FIND THE RIGHT TOOL FOR YOUR APPLICATION

Composite Printing

Solutions

Metal Printing

Solution