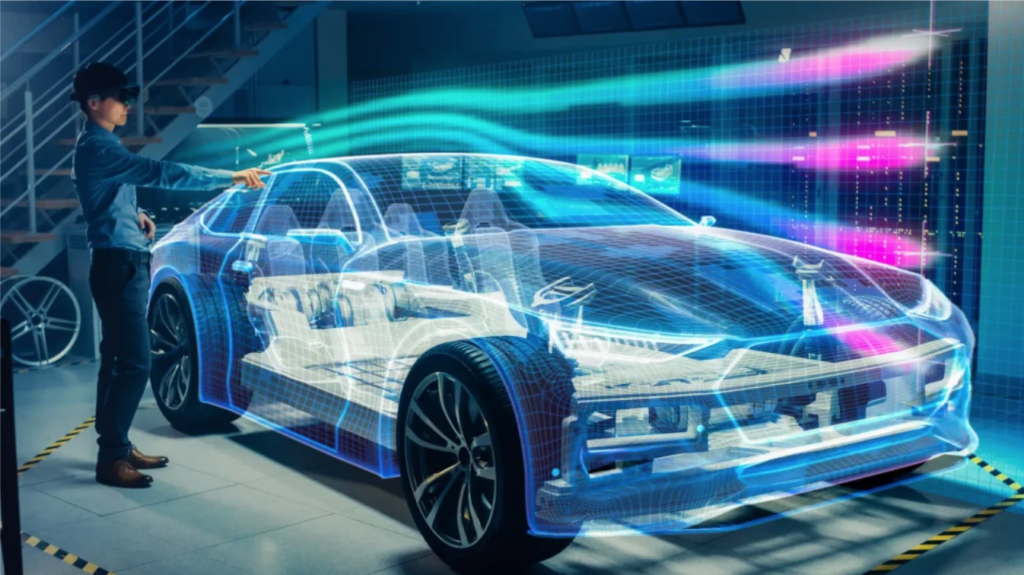

The automotive industry is navigating a transformative era. With advancements in electric vehicles, sustainability initiatives, and the demand for lightweight yet durable components, manufacturers are rethinking how they design, test, and produce. Here’s how advanced applications empower innovation…

Key Applications and the Companies Succeeding

Reducing vehicle weight directly enhances fuel efficiency and performance. By leveraging materials like carbon fiber and 3D printing technologies, automotive manufacturers can produce lightweight, high-strength components for structural reinforcements, brackets, and interior features.

General Motors (GM) has utilized lightweight composite materials and advanced manufacturing techniques to reduce the weight of their vehicles. The use of 3D-printed components has helped in creating strong and lightweight parts that contribute to overall vehicle efficiency and performance.

Simulating airflow dynamics is critical for designing energy-efficient vehicles. Using Computational Fluid Dynamics (CFD) tools, engineers can optimize vehicle shapes to minimize drag and maximize performance, significantly reducing time spent on physical prototypes.

Tesla has been at the forefront of aerodynamic optimization. By applying CFD simulations in their design process, Tesla has been able to enhance the aerodynamics of their electric vehicles, leading to higher range and better energy efficiency.

Safety remains a top priority. Advanced simulation tools allow manufacturers to perform virtual crash tests, identifying weaknesses and optimizing structures for durability. This minimizes costly physical testing and ensures compliance with regulatory standards.

Volvo, known for its emphasis on safety, has used simulation tools extensively to design and test vehicles for crashworthiness. Their approach helps in reducing the number of physical prototypes needed and ensures compliance with stringent safety regulations.

Additive manufacturing enables rapid prototyping and the production of jigs, fixtures, and functional components directly on the shop floor. This improves lead times and reduces the need for complex supply chains.

Ford has embraced additive manufacturing for creating prototypes and production tools, which has significantly shortened lead times and allowed for more agile design processes.

Realized Benefits

- Improved Time-to-Market: Faster prototyping and iteration cycles with integrated design and manufacturing workflows.

- Cost Savings: Reduced material waste and fewer physical prototypes.

- Sustainability Gains: Adoption of lightweight materials and efficient processes reduces environmental impact.

Empowering Automotive Innovation with GSC

GSC’s expertise ensures manufacturers stay ahead of the curve by providing the tools and insights needed to meet modern automotive challenges. Let’s partner to drive your success forward.

Contact us today: Click Here

Share

Meet the Author