In medical device manufacturing, innovation is key to developing cutting-edge solutions that enhance patient outcomes. One crucial element in achieving this innovation lies in robust simulation and analysis tools. Among the leaders in this domain is SIMULIA, a comprehensive suite of simulation software that empowers engineers in the medical device industry to redefine the boundaries of design and functionality.

Mastering Advanced Simulation Capabilities

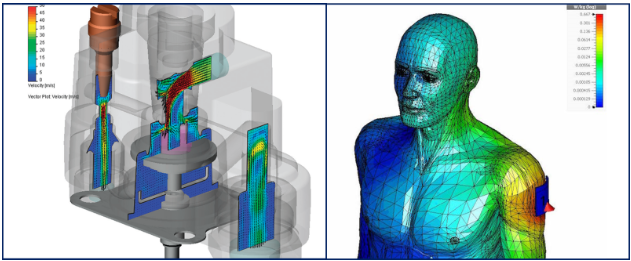

At the heart of SIMULIA is its advanced simulation capabilities, particularly within the Abaqus suite. Engineers can delve into intricate finite element analysis (FEA) and computational fluid dynamics (CFD) simulations, offering unparalleled insights into the structural, thermal, and fluidic performance of medical devices. This capability is a game-changer, allowing for a deeper understanding of device behavior under varying conditions.

Biomechanical Analysis for Implants & Prosthetics

For medical devices intimately connected with the human body, such as implants and prosthetics, SIMULIA’s biomechanical analysis tools shine. Engineers can simulate the interaction between devices and biological tissues, paving the way for more accurate predictions of device behavior in real-world scenarios. This ensures that devices are not only functional but also safe and comfortable for patients.

Ensuring Structural Integrity & Durability

The validation of structural integrity and durability is paramount in medical device manufacturing. SIMULIA empowers engineers to conduct comprehensive analyses, assessing stress distribution, fatigue life, and deformation under diverse loading conditions. By ensuring the durability of medical devices, SIMULIA helps manufacturers meet stringent regulatory standards and instill confidence in the reliability of their products.

Optimizing Fluidic Dynamics for Precision Instruments

Fluidic dynamics play a pivotal role in various medical instruments, from cardiovascular devices to drug delivery systems. SIMULIA’s fluidic dynamics simulations allow engineers to model and analyze fluid behavior within devices. This capability facilitates the optimization of designs for efficient fluid flow, reducing turbulence and ensuring precise functionality in critical medical applications.

Materials Optimization & Performance Prediction

Selecting the right materials is a cornerstone of medical device design. SIMULIA aids engineers in optimizing materials by offering simulations and analyses of material properties under different conditions. This ensures that materials not only meet performance requirements but also comply with regulatory standards, laying the foundation for safer and more effective medical devices.

Virtual Prototyping & Iterative Design

In the race to bring innovative medical devices to market, time is of the essence. SIMULIA enables virtual prototyping, allowing engineers to iterate through design changes without the need for physical prototypes. This not only accelerates the design process but also reduces costs associated with traditional trial-and-error methods, giving engineers the flexibility to refine and optimize designs swiftly.

As the medical device manufacturing industry continues to evolve, SIMULIA stands out as a transformative force. Its advanced simulation capabilities, coupled with a focus on biomechanical analysis, structural validation, fluidic dynamics, and materials optimization, empower engineers to push the boundaries of innovation. In a sector where precision, reliability, and safety are non-negotiable, SIMULIA emerges as a trusted partner in shaping the future of medical device design.

Learn More Here

Share

Meet the Author