CAMWorks held their 2019 Global Partner Summit LaunchPad conference May 19-24. Attended by VARs and industry professionals, this year’s event had the largest attendance in history. The Wild Horse Pass Sheraton hosted the event and GSC sent three representatives: President and CEO Dave Kasinskas, VP of Sales Josh Kasinskas, and myself.

While LaunchPad is traditionally sales-oriented, the attendees received a wealth of technical knowledge and insights into items in development.

Conference Highlights

CAMWorks ShopFloor

CAMWorks’ Data Management Solution for manufacturers, ShopFloor provides a one-stop solution for maintaining and accessing information by members at every level. ShopFloor automatically generates setup sheets, toolpath simulations, and allows operators to visualize the changes they make in real-time. CAMWorks ShopFloor also checks each data set against the model to ensure everyone is working with the most recent version. ShopFloor can be combined with SOLIDWORKS PDM to create a system that’s second-to-none.

CAMWorks Additive

With the proliferation of Additive Manufacturing, or 3D Printing, more customers are using the emerging technology for prototyping and production. CAMWorks Additive was released in 2019 to great fanfare and has lived up to the hype.

“38% of current manufacturers expect to use Additive Manufacturing (AM) for end-parts by 2021” – EY Global Printing Report.

CAMWorks partnered with industry-leader Materialize to provide a unique solution for metal printing entirely within the SOLIDWORKS platform. The resulting print information is then stored within CAMWorks so traditional subtractive manufacturing processes can be used to finish a part while maintaining complete associativity.

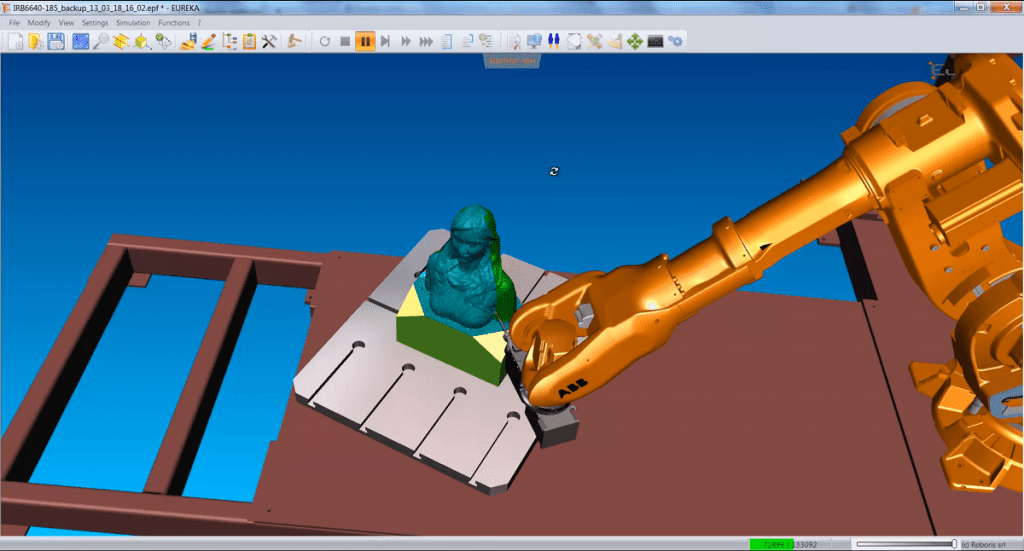

Eureka Virtual Machine Simulation

Many users of CAMWorks will be familiar with the Eureka name; they provide the basis for CAMWorks virtual machine simulation which allows users to see their machines in motion, verifying the output G-Code works flawlessly. At the LaunchPad event Eureka made waves by demonstrating they can now apply the same simulation technology to move robotic arms in a virtual world. The entire manufacturing process was represented by programming for a part was performed in CAMWorks, output using a post-processor that generated APT formatted G-Code, and accurately simulated using Eureka 9.

Paul Yaffe Motorcycles

As seen on the TV Show “Great Biker Build Off,” motorcycle builder Paul Yaffe brought their customized motorcycle, Suzy-Q, and talked about how they use SOLIDWORKS CAM and CAMWorks for both production and one-off components. With CAMWorks’ Automatic Feature Recognition and Technology Database, designers at Paul Yaffe are able to program parts in minutes that had taken hours with their previous CAM software. This automation allows them to focus on creating truly unique designs instead of worrying about where to find the time to manually program their parts.

The Future is Bright

All-in-all, the event was a great success and brought VARs from around the world together. The bar has been set high but next year’s conference will undoubtedly be even larger and more informative. If you want to learn more about CAMWorks, let us know by calling 800-454-2233 or if you don’t want to talk on the phone, give us a heads up about your interest through our online form.

Share

Meet the Author