“Simulation Tools Are Too Expensive & Too Complex for My Organization!”

This is a common phrase I hear. People look at purchasing an expensive, but valuable, new tool like Simulation Software, and are often dissuaded from making the purchase for 3 reasons:

- They feel the price is too high!

- They feel the product will not perform as represented.

- They feel that the tool will end up sitting on the shelf, because of lack of proper training or it’s just too hard to break previous habits of operation.

They feel is in bold, because these 3 reasons are often considered in moments. Have you ever read Blink, by Malcolm Gladwell? If not, I strongly suggest it as I found it to be enlightening and the author describes this concept in depth. For the sake of this article I will keep it short. We’re constantly making very quick decisions from the subjective and emotional side of our brain. We make these very quick decisions and judgments all the time without fully considering the reasons why.

It’s not saying that these decisions are incorrect, but if we are looking at a concept that’s truly different than what we have known or experienced our brain will always choose safety. We have to know ourselves and how our brain functions to fully allow ourselves to consider novel concepts before completely dismissing them.

Once you have acknowledged the thought process, you need to ask yourself the right questions when considering an advanced tool like simulation:

- Will the product perform as represented?

- What will the tool cost? (Initial purchase, yearly license, training, operational costs)

- What will I gain in using the tool? (reduced product development and improvement times, reduced warranty/liability costs, reduced Engineering time, reduced material costs, …)

- Assuming 1 is a resounding Yes, then only 1 questions remains. Is 3 > 2? ( If this answer is also Yes, then acquiring the new tool should be a priority immediately.)

Now bringing Simulation in-house isn’t for everyone, but if you take an honest look at the previous 4 questions you may find that you haven’t fully taken advantage of an existing tool that could take your company to the next level.

Let’s dive into an example with Manufacturer X… they make Generators.

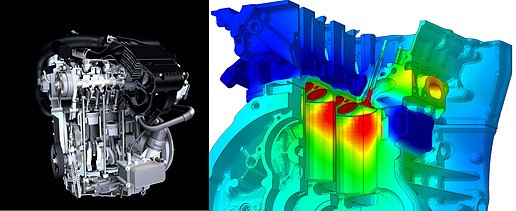

I’ve had the pleasure of attending Engineering Speaker Series events hosted by a top Generator manufacturer in the U.S. They discussed Finite Element Analysis (FEA) and how they had been using simulation to improve their New Product Development (NPD) process. They were using FEA to reduce the cost of bringing a new Engine Crankcase design to market. They were able to prototype 1 Engine Crankcase for physical testing purposes and, using simulation, were able to model 8 iterations of the design to reach their final product.

Before implementing simulation, their process was to design an Engine Crankcase, make the prototype, physically test, make design modifications, and repeat those steps until they were happy with the end product. In their traditional method it would take about 1 month to complete all of the appropriate physical tests for design validation of 1 iteration. To conduct the same tests through simulation the process took 3 weeks for 5 iterations. Now pair the physical testing time, with the time to update a new crankcase CAD model, and the time to receive your new custom aluminum crankcase prototype, times 8 and the decision for them was probably a no-brainer.

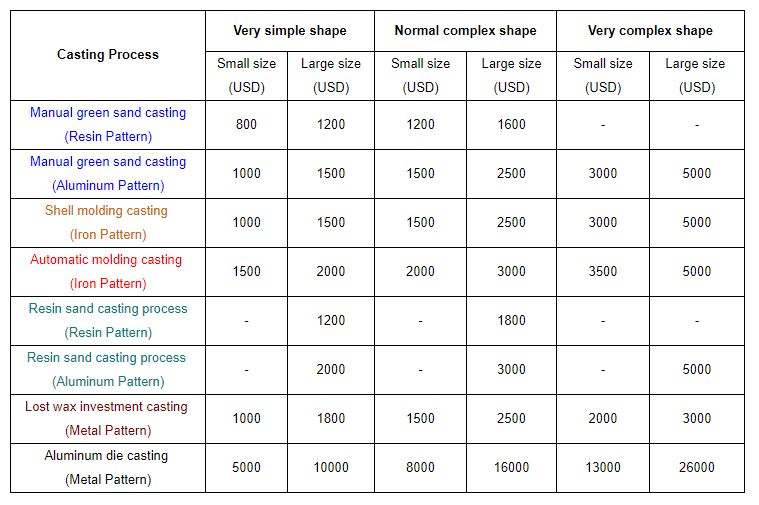

Below is a chart from www.iron-foundry.com, to provide an idea of the cost to create a custom aluminum cast prototype.

So let’s answer the 4 Questions for Manufacturer X.

- Since they purchased the simulation software and conducted the training necessary to use the tool we can assume they went through demonstrations to prove that the simulation tool would work for their purposes. So we will check 1 off of our list as a Yes.

- Now analysis software such as ABAQUS, ANSYS, Nastran, etc. can have a wide ranging price depending on use, users, solving speed, etc. So for the purpose of this example I will use the nice round number of $50,000 for a yearly license and training. (And no, you can’t skimp on the training. If your team isn’t properly trained to use the tool, then you could be setting up your organization for a headache which will only prove your original doubts. Always fully invest in what is needed!)

- Using the chart from iron-foundry.com we’ll use the $26,000 as the casting price for their Engine Crankcase. We are also going to neglect any warranty/liability gains for this estimate. The cost to produce 8 different models: 8 x $26,000 = $208,000 for Materials. Let’s assume an Engineer, with a salary of $85,000, was used for 8 months conducting the physical testing for the 8 engines. Engineering Time: $85,000*(8/12) = ~$57,000. By implementing the software 1 prototype was ordered for physical testing (Material = $26,000), and 2 months were required for physical testing and simulation iterations (Engineering Time: $85,000*(2/12) = ~$14,200). Now because I personally would like a final physical product validation I would probably order a final prototype with the ideal simulated model changes boosting our Material cost to $52,000 and Engineering Time Cost to $21,250. Money saved is money earned so by adding up our traditional costs and subtracting our new method costs Generator Manufacturer X gained: $208,000+$57,000 -$52,000-$21,250 = $191,750 and 5 months of Engineering Time!

- So 1 is a Yes, and 3 ($191,750) is significantly greater than 2 ($50,000), so it looks like Manufacturer X made an excellent choice in choosing and utilizing Simulation.

It all comes down to Return on Investment.

It’s very important to be able to make quick accurate decisions, but sometimes it is worth it, to take a step back, evaluate your process, and ask some questions. Once you sit down and take a real look at your current Engineering issues and compare them with how they can be tackled with Simulation or other advanced tools you may find a lot more money and time available for other aspects of your business.

Let Us Know

If you have any questions on Simulation tools, features, functionality, prices, training, or similar inquiries, feel free to reach out to GSC at 800-454-2233. Our online contact form is also available.

Share

Meet the Author