The concept of 3D printing anything and everything is a common thought amongst many individuals. While that hasn’t occurred and probably won’t for a long time, additive manufacturing is quickly becoming a need for many manufacturers, and it’s easy to understand why.

Although 3D printing originated over 40 years ago, at its inception, it was predominately used for prototyping. Today 3D printing is no longer utilized solely for consumer base purposes such as printing one-of-a-kind objects. It is now being used heavily in manufacturing settings to produce functional, large-scale, and end-use products.

The Revolution of Materials

The evolution of technology and engineering-grade materials has allowed companies to use additive manufacturing to streamline existing processes and produce high-quality parts.

Nick Schmidtke, our 3D Applications Engineer, says though 3D printers have improved in terms of accuracy, dependability, and repeatability, the advancement in materials has had an immense impact on many manufacturing companies. New materials and material alternatives have allowed manufacturers to produce high-end custom parts that wouldn’t be economical in other ways.

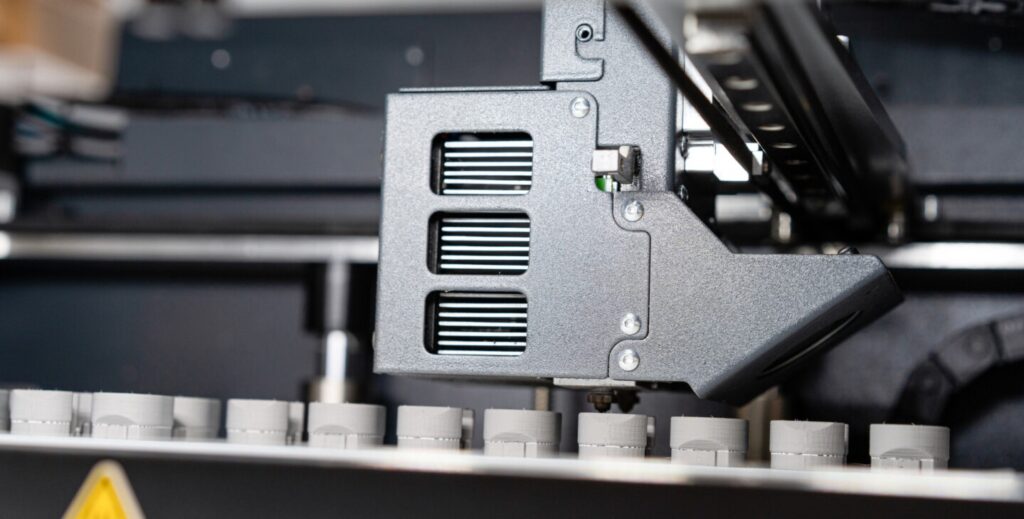

GSC’s customer Johnson Level, a leading provider of levels, lasers, and layout tools, uses their Markforged Mark Two industrial-grade 3D printer for many projects. Within the first nine months, they implemented new composite material parts on at least four production projects and saw a 90% cost reduction in tooling.

Markforged has been a huge game-changer in the development of new materials. The Continuous Fiber Reinforcement printing technology that Markforged pioneered allows manufacturers to print durable end-use parts. With new materials and composites, manufacturers can confidently and repeatedly print items as strong as aluminum to use on the manufacturing floor.

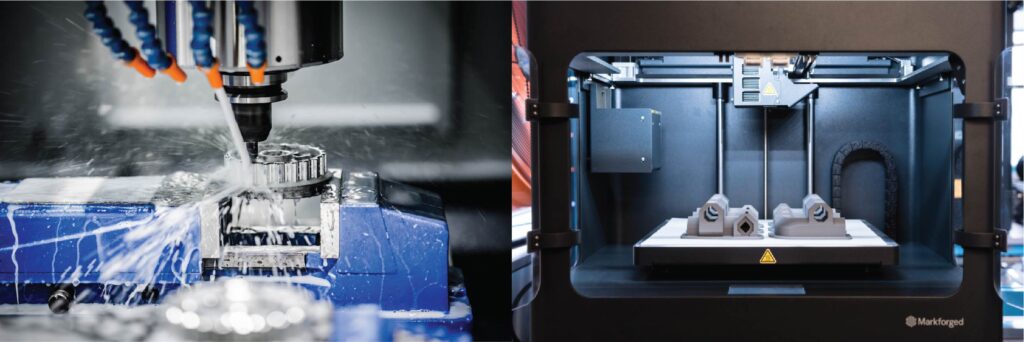

Subtractive Manufacturing Meets Additive Manufacturing

Many companies have reaped the benefits of implementing additive manufacturing into their processes – especially those who typically use subtractive methods such as CNC machining to produce end-use parts.

Additive manufacturing requires less manpower and can function autonomously, reducing material waste to quickly produce solid and light parts.

“With additive, there is also no need for G-code creation, and now manufacturers can produce very similar parts much like what we would see in a CNC machine,” Schmidtke notes.

Many companies have also avoided supply chain concerns by reducing manufacturing costs and lead times by over 90%. It has also given them a competitive edge by executing projects more quickly.

Whether you need one component or 5,000, our 3D printing professionals will help you select the appropriate materials and 3D printers to transform your company.

Interested in Learning More?

Watch our on-demand 3D printing tour with a staff guide.

Contact Us

Schedule an in-house personal tour to speak with our additive experts!

Share

Meet the Author