In today’s rapidly evolving manufacturing landscape, automation has become the key to staying competitive and efficient. Integrating 3D printing into automated manufacturing systems has unlocked a new world of possibilities, enabling manufacturers to enhance productivity, reduce costs, and streamline production. But what exactly makes 3D printing such a valuable tool for automated manufacturing?

In this blog, we’ll explore the top five benefits of using 3D printing in automated manufacturing and why more companies are embracing this powerful technology.

1. Rapid Prototyping & Iteration

One of the biggest advantages of 3D printing is the ability to quickly design, test, and refine parts or components in-house. Traditional manufacturing methods often require expensive molds, tools, and long lead times to create prototypes. 3D printing, on the other hand, allows manufacturers to print prototypes in a matter of hours or days, depending on the complexity of the part.

For automated manufacturing, this rapid prototyping capability means you can design custom fixtures, jigs, or tooling to optimize robotic processes. Engineers can quickly iterate on designs to ensure that the part fits and performs perfectly within the automated system, leading to faster production cycles and improved overall efficiency.

2. Cost-Effective Customization

In automated manufacturing, custom tooling and fixturing are often required to handle specific tasks or materials. Producing these custom components with traditional machining processes can be expensive and time-consuming, especially for low-volume or one-off parts.

3D printing offers a cost-effective solution by enabling manufacturers to produce highly customized parts at a fraction of the cost. Instead of investing in specialized machinery or outsourcing custom parts, you can print them on demand using materials like nylon composites, carbon fiber, or metal. This flexibility allows manufacturers to quickly adapt their automated systems to changing production needs without the high costs traditionally associated with customization.

3. Reduced Lead Times & Downtime

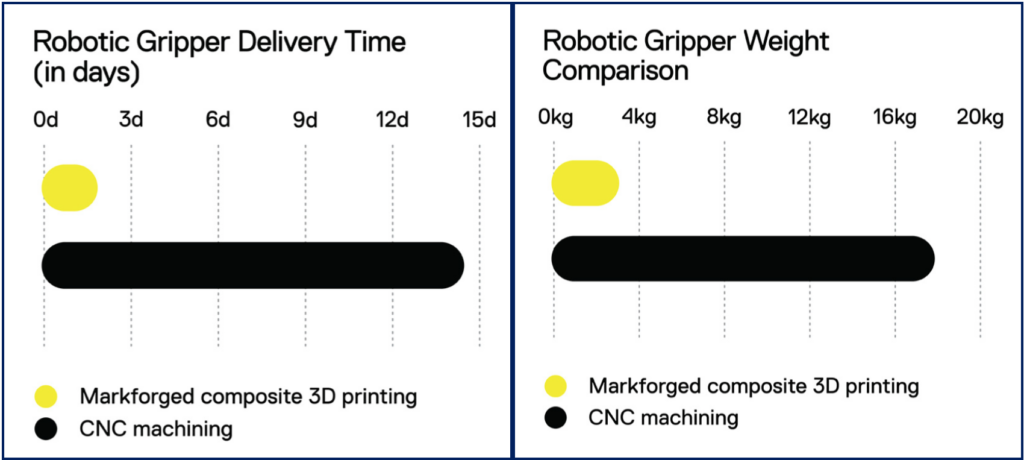

Time is money in manufacturing, and minimizing downtime is essential for maximizing production efficiency. With 3D printing, manufacturers can significantly reduce lead times for producing replacement parts, tools, or components needed for automated systems. When a tool or fixture fails, it can often take days or weeks to receive a replacement from a supplier, causing costly production delays.

By having a 3D printer on-site, manufacturers can print spare parts or custom tooling whenever needed, eliminating long wait times and reducing downtime. This on-demand production capability keeps automated manufacturing lines running smoothly and allows companies to meet tight deadlines with greater flexibility.

4. Increased Design Freedom & Innovation

One of the most exciting benefits of 3D printing is the design freedom it offers. Traditional manufacturing methods are often limited by the capabilities of the equipment used to produce parts. With 3D printing, designers and engineers are free to create more complex geometries, lightweight structures, and intricate internal features that would be impossible or prohibitively expensive to achieve with conventional methods.

For automated manufacturing, this increased design freedom means that parts and tools can be optimized for performance, weight reduction, and ease of integration into robotic systems. Innovative designs can lead to more efficient workflows, improved part handling, and enhanced product quality, all of which contribute to a more streamlined and effective automated manufacturing process.

5. Material Versatility & Durability

3D printing offers a wide range of materials suitable for automated manufacturing, from engineering-grade plastics to carbon fiber composites and even metal. This material versatility ensures that manufacturers can produce parts that are both lightweight and durable, perfectly suited for the high demands of automation.

For example, materials like Markforged’s Onyx (a nylon-carbon fiber composite) or continuous fiber reinforcement provide exceptional strength and durability while remaining lightweight. These materials are ideal for creating end-of-arm tooling, custom fixtures, or specialized components that can withstand the rigors of automated processes.

Moreover, the ability to print parts with multiple materials in a single process allows manufacturers to tailor the properties of each part to specific functions, ensuring that critical components in automated systems meet performance and longevity requirements.

As the manufacturing industry continues to move toward greater automation, 3D printing has emerged as a vital tool for enhancing efficiency, flexibility, and innovation. By enabling rapid prototyping, cost-effective customization, reduced lead times, increased design freedom, and material versatility, 3D printing is transforming how manufacturers approach automated production.

If you’re looking to take your automated manufacturing processes to the next level, consider integrating 3D printing technology into your operations. Contact GSC today to learn more about our 3D printing solutions and how we can help you achieve greater productivity and efficiency through automation.

Share

Meet the Author