3D Printing Solutions

Optimize Your Packaging Lines

Food and beverage industry leaders are keeping their lines up and running with on-demand MRO parts and production tooling. Improving throughput, optimizing line changeovers, and ensuring operator safety has become crucial with the growing adoption of factory automation.

The Digital Forge gives manufacturers a simple way to build custom parts in hours instead of days, 3D print replacement parts for aging equipment that is no longer easily serviced by an OEM, and lightweight robotic arms to improve the performance of expensive automation equipment.

Featured Food and Beverage 3D Printed Applications

Custom Safeguards

Manufacturing teams can minimize delays by creating custom safeguards on-site at the point of need.

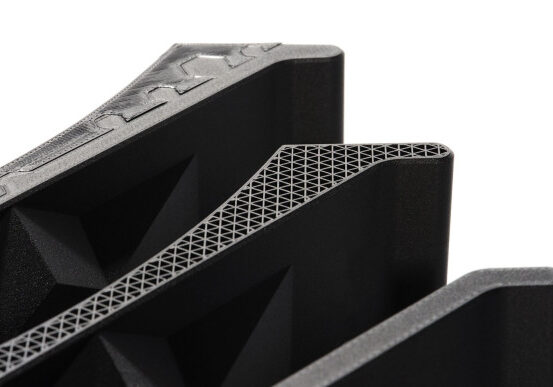

Production End-of-Arm Tooling

Vacuum grippers for pick and place are used in the final packaging step to transport the unit containers into the retail packaging box.

Custom Push-Plate

Expand your production team's capabilities to produce custom pusher components onsite, resolving challenging placements and unique product surfaces/angles.

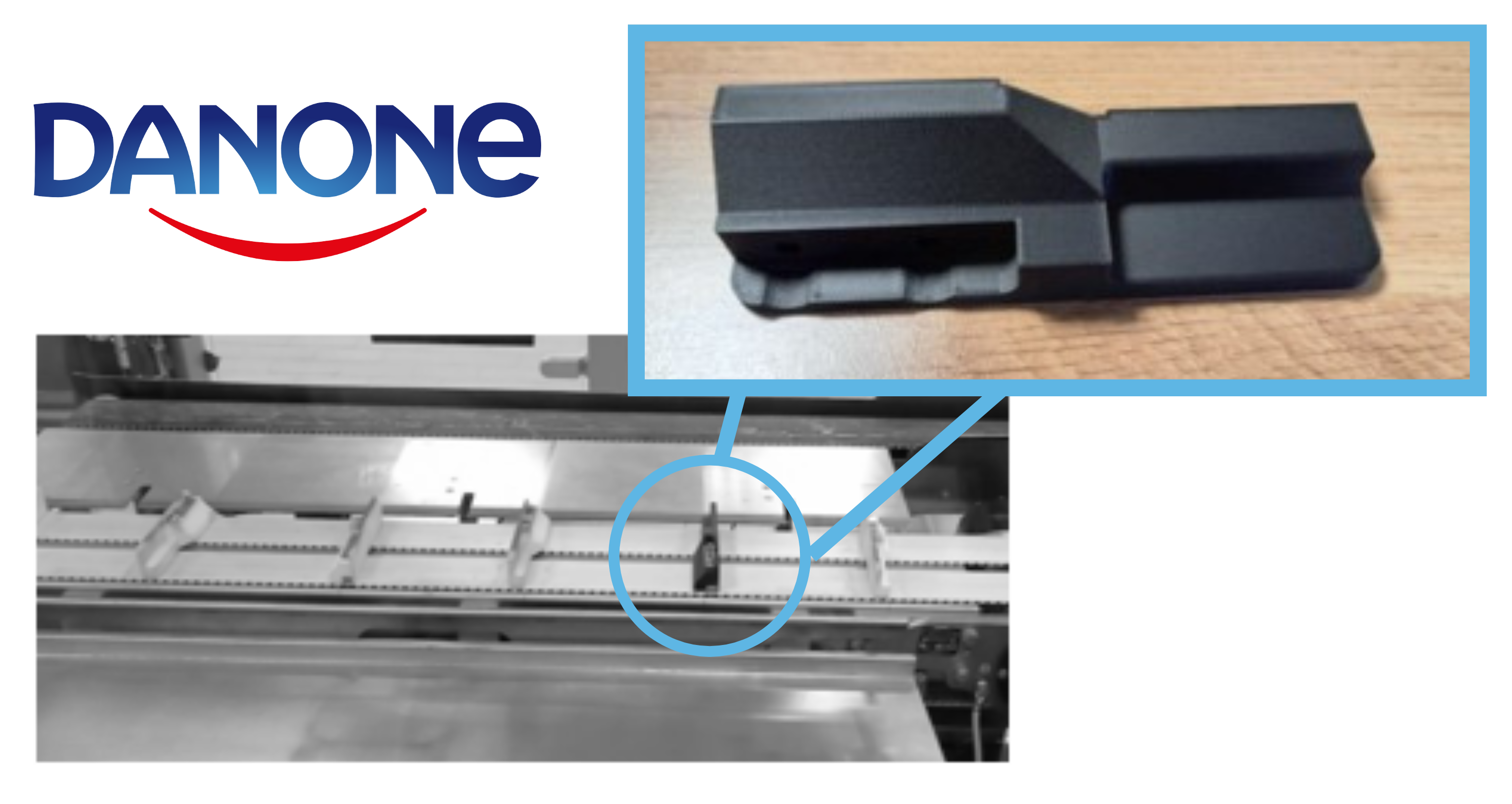

Danone Dairy Plant cut the cost of 374 replacement parts by 80%+ with 3D printing

Start making manufacturing aids at the point of need while reducing production time and costs

Software Solutions

For many years, food and beverage companies have relied on Excel spreadsheets for supply chain planning. The demand for precision, speed, and visibility has increased. Managing numerous stakeholders, a wide range of products, and growing data, alongside disruptions and the need for transparency, indicates that Excel is no longer sufficient.

Dassault Systèmes' 3DEXPERIENCE platform provides a digital solution to help food and beverage companies handle supply chain planning and production scheduling more effectively.

Benefits of 3DEXPERIENCE Platform

- End-to-End Visibility

With the 3DEXPERIENCE Platform, stakeholders have real-time visibility into all aspects of the production process, from product design to manufacturing and quality control. This transparency helps identify bottlenecks, streamline workflows, and make informed decisions.

- Collaborative Environment

The platform offers a collaborative environment where teams can work together seamlessly, regardless of location. This is especially valuable for companies with multiple production facilities or distributed teams.

- Data Management

The platform's robust data management capabilities ensure that all product-related data, including designs, specifications, and compliance documentation, are centralized and easily accessible. This improves data integrity, reduces errors, and facilitates compliance with regulatory requirements.

- Customizable Workflows

Companies can customize workflows within the platform to align with their specific manufacturing processes and business objectives. This flexibility enables them to adapt quickly to changing market demands and optimize operations accordingly.

Integrate From Farmer to Consumer

Every year, global food loss during or just after harvest is estimated at $600 billion, while at the retail end, about 30% of surplus food in US grocery stores ends up in landfills. This highlights the need to curb wastage and protect profits from end to end.

SOLUTION: The 3DEXPERIENCE platform creates a seamless integrated supply chain from farmer to consumer, ensuring ethical sourcing and procurement, accurate planning and efficient production and delivery. Real-time data empowers businesses with visibility and efficiency across supply chain operations and different planning time horizons to achieve:

- 10%-40% improvement in production throughput

-

15%-200% increase in on-time deliveries

-

12.5% savings on operational costs

-

15% reduction in logistics mileage

Software Solutions

The advanced manufacturing operations management solution designed to optimize production processes, ensure quality and compliance, and maximize efficiency for food and beverage manufacturers.

Benefits of DELMIA

- Manufacturing Process Optimization

Provides tools for simulating and optimizing manufacturing processes, such as production scheduling, resource allocation, and layout planning. For food and beverage manufacturers, this means being able to optimize production lines for maximum efficiency, minimize waste, and ensure on-time delivery.

- Quality Control

Helps implement rigorous quality control measures throughout the production process. By simulating and analyzing quality control procedures, manufacturers can identify potential issues early on and implement corrective actions to ensure product quality and safety.

- Regulatory Compliance

Ensure compliance with regulatory standards and industry regulations, such as food safety regulations and labeling requirements. The software helps track and document compliance activities, making it easier to demonstrate regulatory compliance during audits.

- Resource Management

Enable efficient resource management by optimizing the utilization of equipment, materials, and personnel. This helps reduce production costs, improve productivity, and maximize profitability.