Additive Manufacturing Solutions

3D printed casting patterns offer an affordable way to create complex cast parts in production volumes and is a reliable method for metal parts. With the shift to digital production, many have adopted 3D printing. Traditional sand casting is slow and costly, requiring skilled pattern makers. Some manufacturers turn to CNC milling to produce their patterns, but this method can not create certain complex geometries and wastes material. 3D printing automates production, speeds up processes, and reduces costs, breaking free from traditional methods.

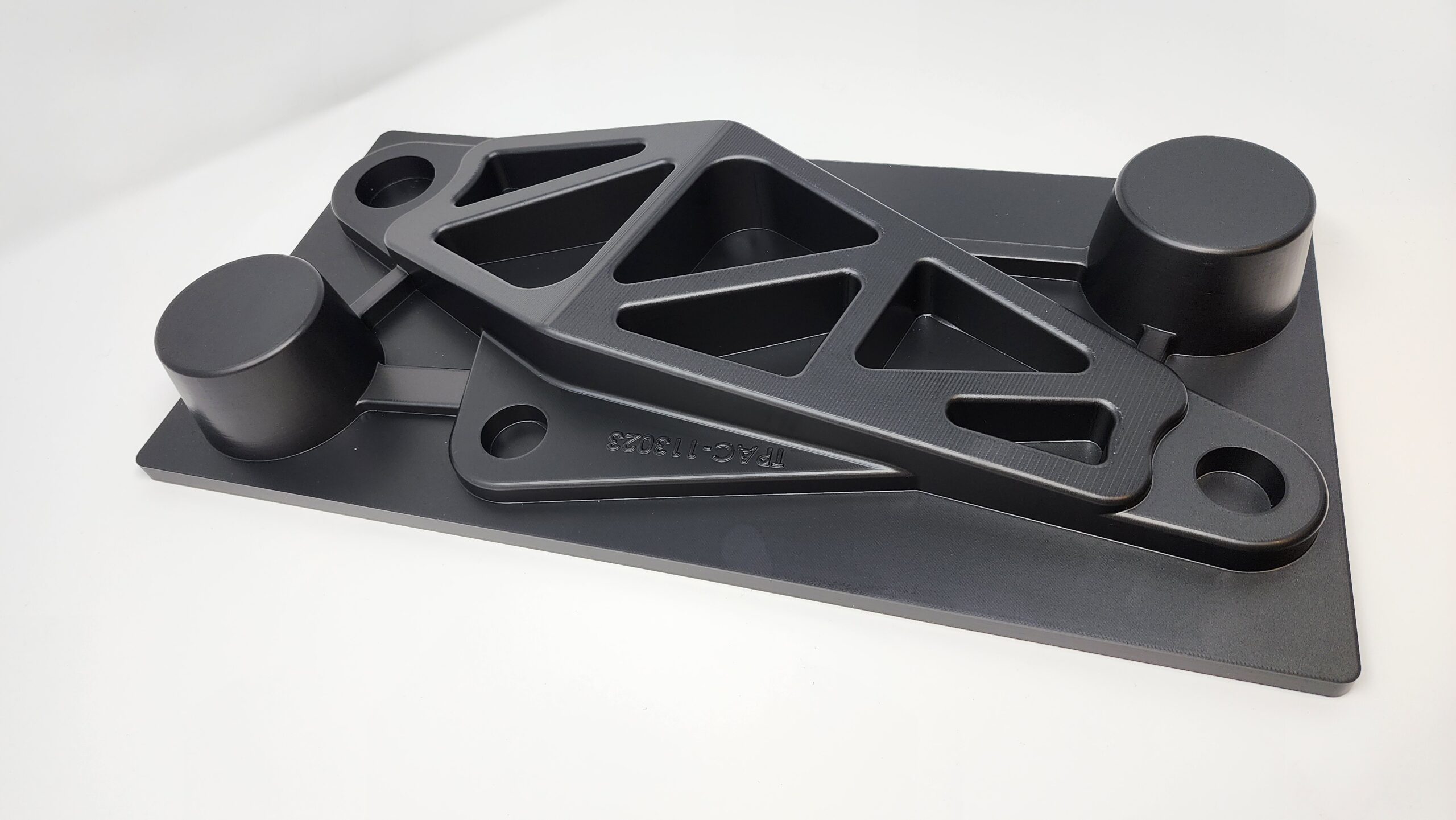

Part: Hose Coupling Sand Casting Pattern

Material: Onyx

Sand Casting Pattern

Material: Onyx

Valmet Foundry: Customer Case Study

Replace Worn Gates & Risers with Onyx Printed Versions

As sets wear out or break, print a new version with just-in-time inventory. Using the Composite Materials, the gates, risers, and heels are as durable as their aluminum/red board materials.

Traditional Process:

- Full day in pattern shop. Additional time for mounting, filling holes, adding leather fillets

- Aluminum or red board materials are significantly higher cost and require extensive machining

3D Printing Process:

- Prints in 1 day

- Fraction of material cost

- No touch time for creation, more durable, resists blasting process, lasts longer

Start creating high-quality, intricate patterns while reducing production time and costs

Software Solutions

SOLIDWORKS 3D CAD provides a comprehensive set of tools specifically designed for creating precise and intricate geometries necessary for casting processes.

SOLIDWORKS 3D CAD Capabilities

- Parametric Modeling

Create precise 3D models with flexible design modifications.

- Advanced Sketching

Capture intricate details and shapes with splines, arcs, and more.

- Feature-Based Design

Efficiently build complex geometries with extrusions, cuts, and sweeps.

- Surface Modeling

Shape complex surfaces for compatibility with various casting processes.

- Assembly Modeling

Visualize and assemble multiple components for product integration.

- Draft Analysis

Ensure optimal draft angles for easy mold release and casting quality.

- Mass Properties

Calculate volume, surface area, and center of gravity for part evaluation and costing.